JOBSCOPE Engineer to Order Software Increases Visibility, Profitability

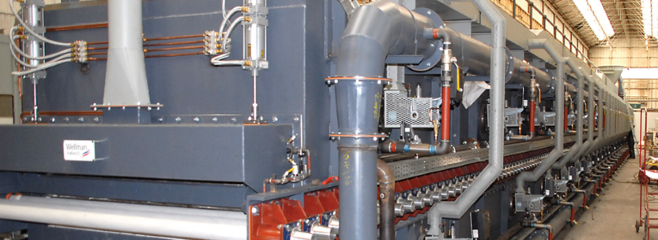

The Wellman Group proves that it is possible to have it all – clear cost visibility and control across the enterprise, plus an engineer to order ETO ERP software system that suits the production methods of each of its individual companies.

The Wellman Group proves that it is possible to have it all – clear cost visibility and control across the enterprise, plus an engineer to order ETO ERP software system that suits the production methods of each of its individual companies.

One of the biggest difficulties in manufacturing automation today is providing engineer to order software capable of satisfying management, engineering, material control, production control, and shop floor requirements. The situation is particularly acute in engineer to order ETO manufacturing where tight cost control over multiple projects does not necessarily go hand in hand with the pressure to get a specific job out of the door on time.

There are many manufacturing ERP software systems that are primarily focused on providing the high level financial reporting that ensures management level popularity. In many cases, however, they cannot demonstrate the adaptability and shop floor  functionality that enables them to serve engineering, material control, production control, and shop floor needs with equal fluency. The manufacturing software industry is awash with stories of efficient manufacturing units that have had to make unnecessary major changes to their operations simply to accommodate the reporting requirements of ERP manufacturing software systems.

functionality that enables them to serve engineering, material control, production control, and shop floor needs with equal fluency. The manufacturing software industry is awash with stories of efficient manufacturing units that have had to make unnecessary major changes to their operations simply to accommodate the reporting requirements of ERP manufacturing software systems.

Under these circumstances, it is no wonder that management level enthusiasm is not shared by engineering and manufacturing personnel; to them it simply means a great deal of extra work for very little direct benefit. What is more, if management level reporting does not adequately reflect the real status of engineer to order manufacturing and engineering operations, their ultimate value must be in some doubt.

In the engineer to order manufacturing environment, managing estimating, engineering, project scheduling, and project cost is particularly difficult. From the earliest estimates all the way through to delivery and installation, the engineer-to-order (ETO) manufacturer needs to be able to allocate resources and identify costs for every element of the project. With both fixed cost/fixed delivery contracts and time and material contracts the need for real time reporting is crucial. Since late delivery often incurs penalty costs, companies need the ability to monitor actual progress against plan (ETC or Estimate-to-Complete) on a project-by-project basis. Individual project visibility is, however, only part of the answer. Remedial action may get one project out of trouble but have serious, adverse impact upon other work in progress. Engineering and Production staff need to be able to track individual projects but also to gain a clear picture of total shop floor loading and capacity in order to avoid bottlenecks and resultant delays and costs.

ETO Software Group Wide Solution

It was against this background that Wellman Thermal decided to implement JOBSCOPE Engineer to Order ETO ERP software as a group wide solution. Based at Oldbury, West Midlands, Wellman employs 220 staff and has a turnover of £35 million. Wellman Thermal encompasses six individual companies; Wellman Group, Wellman Robey, Wellman Furnaces, Wellman Graham, Wellman Process and Wellman Services. All companies use JOBSCOPE Engineer to order manufacturing software.

Wellman Thermal began manufacturing boiler and pressure vessels in the late 1800’s and has expanded to include a range of industrial furnaces and heat exchangers, all for industrial, commercial and military markets. The majority of products are engineer to order and configured to customer specification, although Wellman does make some hot water boilers for stock. Used in schools, hospitals and airports these are stocked for emergency breakdowns and built to stock. They also make fast steam raising boilers for navy frigates and heat exchangers for Texaco, Shell and BP. At any one time the company is handling some 40-50 different contracts, each involving hundreds of shop floor operations.

Wellman Thermal began manufacturing boiler and pressure vessels in the late 1800’s and has expanded to include a range of industrial furnaces and heat exchangers, all for industrial, commercial and military markets. The majority of products are engineer to order and configured to customer specification, although Wellman does make some hot water boilers for stock. Used in schools, hospitals and airports these are stocked for emergency breakdowns and built to stock. They also make fast steam raising boilers for navy frigates and heat exchangers for Texaco, Shell and BP. At any one time the company is handling some 40-50 different contracts, each involving hundreds of shop floor operations.

Increasingly, Wellman is involved in repair and refurbishment. Complexity varies considerably with some jobs taking 50 hours while others take 3,000 hours. Every job, whatever the complexity, is managed in JOBSCOPE ETO software.

Wellman is clear on the business need driving the decision – they wanted a engineer to order software system that would give them full control of capital goods contracts. They required an ERP manufacturing software system that would track actual contract costs, allow planning, engineering, and material control by contract, accommodate both billings based on shipments and progress billings, and be used as a tool to forecast the outcome of individual projects (ETC Estimate to complete).

Strategically the board needed to measure each job against the group regional estimate, which would impact both the current selling price and also show if performance levels were being maintained against forecasted profits. JOBSCOPE ETO ERP Software provides Wellman with the unique advantage of being able to look for savings elsewhere, in order to achieve profit targets. Equally, Wellman has the ability to analyze each project to produce accurate quotes for similar work in the future.

Jobscope’s UK based implementation partner, In2grate, was selected for local implementation support because of its strong background in contract control systems. ‘Jobscope’s & In2grate’s people were a major factor,’ says Group IT Manager Anne-Marie Baillie. ‘They talk from a position of knowledge having experienced manufacturing first-hand.’ JOBSCOPE ERP software is used in its entirety throughout the company, for estimating, creating jobs and works orders, stock and inventory control, dispatch and all financial accounting.

Engineer to Order Software Benefits

Wellman continues to realize the benefits of using JOBSCOPE ETO manufacturing software which include:

- Better control of factory capacity planning

- Ability to forecast outcome of contracts

- MRP & CRM Integration

- High visibility across operations via Forest and Trees report writing

Wellman filled another gap in with the introduction of shop-floor data collection and bar coding. Now there is real-time analysis of labor costs and the company can see instantly the hours and material charged to any job. ‘This is especially useful in knowing where we are in relation to the actual job cost, profit margin, and Estimate to complete (ETC) so we can identify problems early,’ said Baillie. ‘Before, the information could be a month old so the job might be shipped before the actual job costs were known.’

Another failsafe is a series of alarms within Jobscope’s KPI and EIS system. KPI’s and alarms are configured to trigger an alarm if costs or labor exceed budget. An alarm is triggered when stock levels hit pre-set levels with the system raising a fax or email requisition automatically. ‘It gives us a degree of visibility that was impossible with manual checks,’ Baillie said.

Wellman is particularly excited about Jobscope version updates, which provide added benefits like CRM and web based field service reporting, reinforcing Jobscopes continued commitment to the Engineer to Order manufacturing environment. Anne-Marie Baillie concludes ‘JOBSCOPE manufacturing software is so a much part of our business we could not run without it.’

JOBSCOPE ERP  Manufacturing Software Overview Brochure Manufacturing Software Overview Brochure |

View JOBSCOPE ERP Manufacturing Software Demo View JOBSCOPE ERP Manufacturing Software Demo |