JOBSCOPE metal fabrication ERP manufacturing software features the tools for a sound Materials Management program via a time-phased, requirements-driven Materials System written specifically for Steel fabrication and aluminum fabrication manufacturing companies. Being unique to these environments, JOBSCOPE avoids the confusion generated by attempting to operate with forecast-driven software.

JOBSCOPE develops, installs, and supports ERP software for steel and metal fabricators. For more than 45 years, companies using JOBSCOPE have improved material management, forecasting, inventory, work orders, and more.

Metal fabricators, aluminum extruders, steel fabricators, and steel service centers all utilize JOBSCOPE metal fabrication software and steel fabrication software to benefit their operations. Regardless of a metal fabrication companies size or product line, it is safe to state that major improvements can be made to the profit picture by better management of materials.

This especially holds true for metal fabrication, steel fabrication, and aluminum extruders. The benefits of a strong materials management system include reduced scrap, traceability of coil, sheet, billets, and extrusions back to the original suppliers lot or heat number, plus the synergistic improvements resulting from have the right materials at the right time, from reduced inventory levels and from avoiding losses through the anticipation of materials problems.

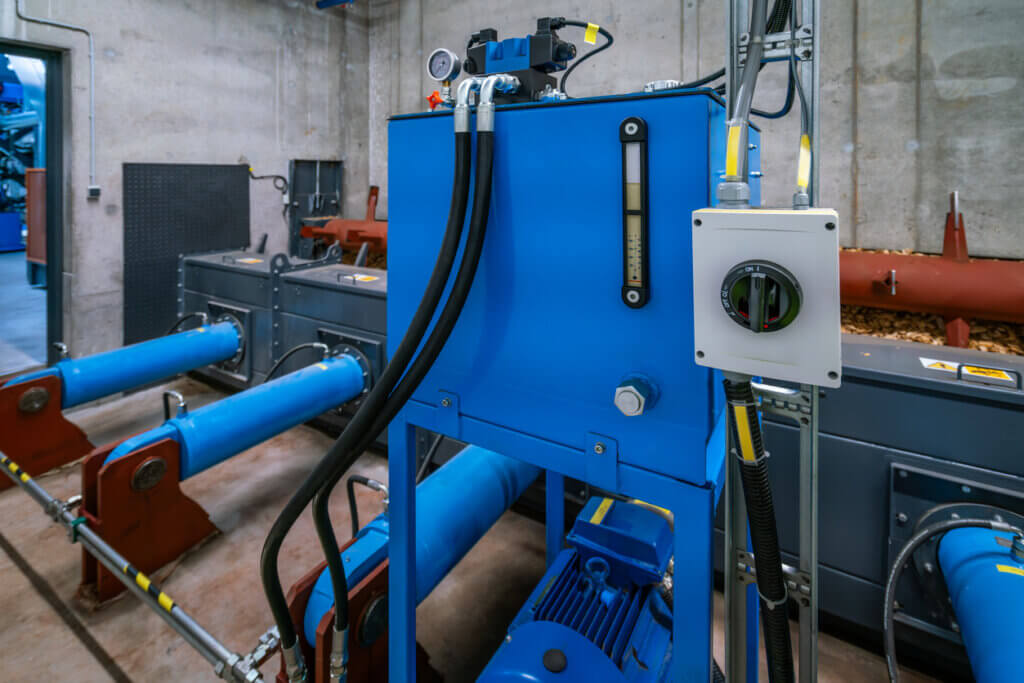

Engineered Products (EP) relies on JOBSCOPE manufacturing ERP software to streamline its metal fabrication processes, from quoting and engineering to manufacturing and installation. As a company that custom-designs and builds material handling systems like pallet racks and automated storage and retrieval systems (AS/RS), EP’s operations demand meticulous project tracking and precise budgeting. JOBSCOPE enables EP to create detailed job records, track labor and material costs, and manage project phases smoothly. Engineers and shop personnel log their time against specific jobs, and materials are ordered and staged as needed, ensuring a seamless transition from design to manufacturing and eventual site installation.

Each EP project typically includes separate jobs for engineering, manufacturing, and installation, all managed under a single contract within JOBSCOPE. As these project phases complete, corresponding jobs are closed, while future service orders and additional contracts for maintenance or updates are easily opened. In addition to project management, JOBSCOPE handles EP’s comprehensive accounting needs, including accounts payable and receivable, balance sheets, income statements, and project-specific cost control. This functionality allows EP’s management team to generate monthly reports for deeper financial insights, helping to monitor departmental costs and detect any accounting discrepancies promptly.

JOBSCOPE also supports EP’s purchasing and inventory management processes, from material ordering to tracking vendor performance and maintaining optimal inventory levels. With real-time data on hand, EP can forecast delivery times based on material availability, efficiently manage project schedules, and simplify inventory counts. By integrating all job costing, inventory, and financial information, JOBSCOPE provides EP with visibility into every stage of production and enables efficient decision-making. This robust functionality supports EP’s commitment to delivering tailored material storage solutions and fuels the company’s growth as it continues to meet specialized customer needs.

“With JOBSCOPE metal fabrication software, we’ve been able to track all of our costs for any pallet rack job. It is a great fit for metal fabrication and every aspect of or manufacturing processes are handled by JOBSCOPE. For us, it’s easy to see where we are at any time for any job.”

Tommy Sinclair

President

Most frequently occurring inventory management available in most manufacturing software solutions. Provides for managing a perpetual inventory through receiving and issuing transactions. Best described as “Stockroom” items and components, or raw materials.

Lots may differ by vendor, size, batch, serial number, heat number, metal type, vendor lot or date received. Within Lot Inventory, JOBSCOPE provides support for three units of Measure (UOM): pieces, pounds, and one other UOM, which is defined by the user. This feature is helpful for serial and lot tracking.

Steel, aluminum and other Items may be purchased specifically for a job, and upon receipt, charged directly to the job. If, however, it is desirable to defer issue to a later date or use it on another job, the materials may be held in the job inventory.

CUSTOMER SUCCESS STORIES

ERP software designed for job-based manufacturing companies across the US.

© Copyright 2025 JOBSCOPE · All Rights Reserved.